Wall tie corrosion has been a big deal in property for about twenty five years. Initially it was seen as a very specialised area; before becoming old hat – something that anyone could do. If fact, when I started out in the mid eighties, all wall tie work had to be specified by an independent surveyor and the completed work certificated by a Structural Engineer or Building Surveyor – not anymore.

So the wall tie scene, is now a mature and somewhat depressed market, with many fewer companies specialising in wall tie replacement – just a few dedicated firms and die hard installers are left.

The thing is, it isn’t rocket science; this wall tie malarkey.

It’s quite straight forward. So you’d think that any decent builder could do it. The trouble is, that the work is hidden from view, it cannot be easily checked for quality and is black magic; as far as customers are concerned. No; clients rely on a piece of paper – a guarantee. This is the scourge of our industry, because it takes customer’s eyes off the job – and on to a piece of paper, made from dead wood. This, often worthless guarantee, rules out the competent, well trained and proven contractor. It lets in the snake oil salesman, with his certificate, printed on parchment and sealed in red.

Yet, now the market is so mature, lots of houses, which were tied by ‘specialists’ in the past, are coming up for sale once more.

Shock horror, all is not well, and the evidence is there to see.

Take this week for instance. I was asked to look at a property in Leeds, which is for sale. The vendor rang me, perplexed “I had the wall ties done on my house twelve years ago, when I bought it – now a buyer’s surveyor says the work is defective and my sale is stalled – help”.

Apparently the buyer’s specialist had said that although some wall ties had been installed, there were not enough of them – and the old rusting ties had not been removed or otherwise treated. The original installer had already been contacted by the vendor and had simply said “I know what I did and it was right”. That’s fine then.

Sale stalled.

On visiting the house I find that it is a semi, with a ground floor built with a cavity wall, of naked brickwork, peppered with dots, where wall ties have been installed. The upper elevations are white painted render and obviously solid brick, with no cavity to tie. Why then was there a pattern of ‘made good’ holes over the render, apparently tying a wall, which never needed any ties?

A quick scan with a metal detector confirmed that the original rusting ties in the cavity wall areas were still there, not removed – not isolated or cropped off, or treated in any way at all.

Horizontal cracks could be seen, in the bed-joints at the old tie position, which is a sure sign of advanced wall tie corrosion and underlines the importance of not ignoring them during the remedial work.

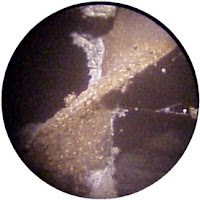

Anyway, I go through the motions, by drilling some holes at the old tie positions so I can have a look with a boroscope. Sure enough, very rusty fishtail ties are present and correct.

Bear in mind that my client is the vendor, so he’s not happy. Furthermore, despite the fact that I am not charging for this survey, he is already telling me that a third ‘specialist’ is coming to give a quote, so my quote had better be low……….long sigh.

As I sense a dispute, between the vendor and his installer – and the buyer and his ‘specialist’, I take the trouble to demonstrate that the upper walls are solid, (it’s obvious, but hey – all specialists like me are cowboys, so I feel the need to prove everything I say, is true).

This is good news and bad news in equal measure. Bad for the vendor, because his wall tie job, paid-for twelve years ago, was a rip off, in that what was done was done badly and more than half of what was done, wasn’t needed anyway. Why did a specialist charged him for tying the solid walls?

The original guy cannot have just made a mistake, because he or his staff have drilled the rendered walls – as if a cavity existed.

It’s bad news for the original installer who is shown to be either; an incompetent fool, a dishonest cowboy, or both.

It’s bad for the new buyer’s specialist, because whilst he has been able to point out the poor wall tie technique used by the previous specialist, he hasn’t spotted that half the house is solid brick and doesn’t need any work at all– hence the quote he has given to the buyer – for a cool three thousand pounds.

And surprisingly it’s even bad for me. Because despite issuing a report which is accurate and a quote which is fair – I may be undercut by another installer, with the knowledge or moral standing of the guy who had a go at this one, twelve years ago. Bear in mind that it is the vendor who is fishing for a cheaper quote – the same guy who was ripped off by a cheap cowboy twelve years ago – and is now keen to make sure that his buyer gets the same opportunity.

Oh, the good news is that building surveyors and valuation surveyors are still asking for a ‘specialist’ report on wall ties, with no recommendation for PCA or WTIF membership or independent certification, or retention. Which means that both of the incompetent/crooked installers, who star in the above farce, can look forward to a bumper 2010.

As I look at my own technicians NVQ’s in Wall Tie Replacement, with the City & Guilds of London stamp on the front, my Investors In People plaque, my proffesional indemnity insurance certificate and my Property Care Association and Wall Tie Installers Federation membership certificates, I think…..what’s the point?

DryRot

Do not despair!

In my recent experience the surveyor who reported on wall ties in my property, a week ago, did insist on a further survey carried out by a WTIF member. The mortgage company also required the same qualification from any company that carried out remedial work, else they would not release any funds.

Thanks – yes there are a few surveyors who are recommending WTIF and PCA members now – thank god. There are still many cowboy jobs slipping through though.

I’ve just used a WTIF recommended installer and he failed to detect & isolate more than 50% of the ties. After him completing the job I’ve been over with a £30 wall scanner and found so many ties. I confirmed this by digging around in the mortar at a couple of locations and he-presto – rusty wall ties. How could his “state of the art” scanner not find them! The big problem is, after he was done we had the wall cavity insulated and so when he has come back to isolate the ties i’ve found there’s a fair chance that the mortar they push back onto the insulation is going to cause a damp problem (it’s also going to invalidate the insulation guarantee). I’m so upset. He’s supposed to be the professional and i’m supposed to rely on him knowing more about it than i do! Any advice on how i get him to do a complete job when he comes back would be much appreciated! Do i have to go over the whole house myself with a scanner or do i just have to bite the bullet and get a surveyor.

Hi Mark,

I can understand your concern and it doesn’t sound good. However, the installer must comply with the WTIF code of conduct and is supposed to install to BRE 329 and 401.

I cannot comment on a WTIF or PCA member’s work directly as that would be against the rules and unethical.

However, I can recommend the following:

Contact the installer and have him come to site and present your concerns to him. He should address these for you and make sure that the problems are put right. If you have doubts then contact the WTIF and check that he is a member. If he is they will offer an inspection and help sort out a repair specification. They may also be able to offer supervision and certification, though of course you can get your own structural engineer to do this. If ther are such serious ommisions then you may be justified in asking the installer to pay for the independent supervision and certification.

As for the insulation, ther are ways of reducing the contamination of the insulation during installation, however any guarantee you have from the insulators will be comprimised I think.

I hope the above works out for you and I will reply via direct email so do contact me again if you need further advice.

Thank you for your comment, I hope you have found the blog useful.

regards

Bryan

Well, they came back today and used my scanner from Argos to “finish the job”. I can’t count the number of lies and excuses he’s spun me today. They missed 47 ties in total (about 70%). He said that using a boroscope or doing a pull-out test isn’t required. I also noted that he didn’t use a diamond pattern with the new ties. He said that also wasn’t required, but i pointed him back to his quote which says it will be a “diamond pattern to be in accordance to the standards”. Previously he didn’t put in any new ties below the DPC (the DPC is a meter high at the front), so that’s been done now. Apparently he’s spoken to the WTIF today to inform them of his mistermeanours and they are still going to guarentee the work. Maybe i’ll check with them to be on the safe side before i send him a check? Thanks again. Mark

Hi Mark,

Mmmm.

As I say I cannot comment directly but the failure to tension test the installation is a worry – how does he or his techncians know that the inner leaf connection is secure? Missing one or two old ties can happen to even the best; we’re all human, but 70% is not one or two and this is fundamantal to the installation.

I’d recommend you have a chat with the WTIF yourself, to make sure they are aware of this. They may wish to inspect or review the members training and quality controls.

Bryan