I love my moisture meter. The one I use most of the time is a General Electric MMS. This is a multi function unit, with conductivity and radio frequency mode. It also has air temperature, humidity and surface temperature modes, with firmware that calculates dew points. Data can be saved and downloaded to a PC for subsequent plotting in a spread sheet.

But let’s not get carried away with all that; the conductivity mode is the daddy for damp work and that’s what I’d like to look at in this post.

The principle is straightforward; dry wood or masonry will conduct less electricity than wet. Thus, when moisture is present, the meter will reflect this. My meter; like most, is calibrated to an average softwood. So when the twin probes are pressed into wood, the meter will express a quantitative reading. In effect if 12% is displayed on the meter’s display, it’s right thereabouts. It’s 12% Wood Moisture Content.

However, stick the meter is anything else; plaster, brick, stone or mortar and the reading is only qualitative – if the meter says 12% – you can discount that completely; the true moisture content of the material may be higher or lower.

This is because the meter cannot be calibrated to account for the variable nature of masonry. For example, dense concrete may have quite a small pore structure. Let’s imagine a cubic metre of 40 newton concrete; rock hard stuff. If we force a cup of water into this cube and then take a reading with our meter, what could be expect? The chances are that we could get quite a high reading. This is because the very few spaces in the concrete have been filled with water, so it conducts electricity very well. However, a cup of water weighs a few hundred grams, whilst a cubic meter of concrete weighs several tonnes. As a percentage by weight, our cup of water is way below 1%. So in this case the meter is grossly over-reading.

The opposite applies for a very lightweight material with an open structure. Here, we may have a cube of pumice type block. It is full of pores and capillaries. If we add a bucket full of water to that, it’s sucked in, with room to spare. Now our meter under-reads. This is because there are still very many empty pores in our pumice, so conductivity is poor.

So, conductivity meters read real percentages in wood and relative qualitative readings in masonry.

In addition, using the meter in masonry or in wood, demands different approaches, to get useful results. Just because the meter is not accurate in masonry does not mean it cannot help us – it can be very helpful.

Let’s use the meter in wood first…

The most important thing to remember is that wood is a natural material. Timber varies a lot, but there are some basic similarities which you need to remember.

First, water travels along the grain easier than it does across the grain. In addition, heartwood is usually less absorbent than sapwood. Also, when thinking about wood and water, it should be remembered that wood is never really dry. It is hygroscopic and will readily absorb humidity from the air. Humidity is absorbed into the cell structure; the walls and fibres – not into the cell themselves. Even so, wood will absorb quite high moisture contents merely as a result of excessive humidity. Once beyond 20 odd % the wood becomes a suitable host for Wet Rots, Dry Rot and is home from home for many species of ‘woodworm’.

If water is present in such high volumes that the cells themselves are full of water, then this is known as ‘Past fibre saturation’. The fibre saturation point of wood varies, but is usually around the 28% mark. Whilst 20% is quoted as the cut off point for fungal attack, decay actually needs higher levels than this to thrive; ‘fibre saturation’ is ideal for Dry Rot to get going. Even wetter wood is way beyond this level -past the point of fibre saturation.

Fibre saturation is important for two reasons: First, wood will not normally absorb enough humidity to exceed this level, so saturated wood will indicate that there is another water source (there are exceptions to this, such as where the additional water source is condensation physically dripping onto or even forming on wood). Second, conductivity meters lose accuracy once fibre saturation is reached, so suddenly the meter reading may go from 29% to 80%, 90% or even 100%. This is because the wood is so full that conductivity is the same as dipping your meter probes in a glass of water. Bye the way, don’t quote readings of 3% or 5% either; conductivity meters lose accuracy at both ends of the range; better to stick to ‘very dry’ or’ very wet’, when dealing with the upper and lower limits.

On site, we need to be aware of the above. if you are getting readings of 10% to 12% in timber than that timber is dry, for most practical purposes. However, if you place your meter probes on the face of a skirting board and get 12% this does not mean that the rear of the joinery is dry, even 12mm across the grain, the MC% may be high enough to support Dry Rot. Wood is pretty resilient when it comes to water passing across the grain. So if you suspect that there may be a damp problem and you want to check flat sawn joinery like skirting or architrave, always place the meter probes as close as possible to the source of moisture. You can also press quite hard, so the the pins penetrate deep into the wood and the readings reflect the true position.

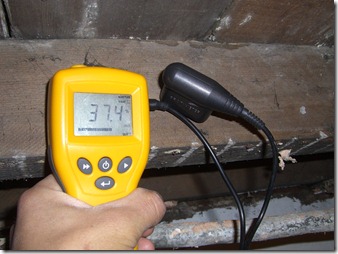

moisture meter testing a floor joist In this image we measure a reading of 37% in this floor joist. That is way beyond fibre-saturation. This level of moisture is unlikely in a joist which is independent of a wall or under a water leak. So, is it really this wet or is our meter over-reading?

Larger section timbers are often quarter sawn, such that there’s older heartwood at one side or edge and young sapwood at another. If you just stick the meter probes in the dense heartwood, you may get a lower reading than that present in the vulnerable sapwood.

Hammer electrodes and insulated probes allow deeper sampling and are essential extra bits of kit.

Moisture meter testing wood This reading is from the face of the skirting. The moisture content of the rear of the timber may be much higher. If you suspect the wall is a source of damp, test the wood as near as possible to it, at the edge.

Now let’s use the meter in plaster…

Remember; all of your conductivity readings are merely a relative guide – they are not a measure of actual moisture content. Only a fool quotes percentage readings obtained from plaster or masonry. I usually quote ‘low’, ‘moderate’ or ‘high’ readings, when referring to data from plaster or any other masonry. I may occasionally say the readings are ‘excessive’ or ‘acceptable’….use your own thesaurus for equivalents.

If you really must quote the readings then the modern accepted parlance is to use the term Wood Moisture Equivalent (WME). So a reading of 65 of your meter could be expressed as 65%WME. In reality this means bugger all, so I don’t bother with WME.

As a handy guide, the MMS unit helpfully quotes – ‘dry’, ‘at risk’ and ‘wet’ below the digital % readout, which you can use if you like, but this is biased to the levels in wood moisture content calibration, so is misleading on masonry.

So in practice the meter has two roles:

As an aid to finding hidden problems; simply poking the meter in walls, here and there may throw up an unexpected high reading. Let’s forget about your eyes finding the causes of damp for now – this post is on the moisture meters, not on surveying technique.

And.….the most important roll, which is as a diagnostic aid, helping a surveyor obtain a ‘moisture profile’. Having located high readings, the meter is invaluable in providing quick data on the relative levels of moisture and the local distribution of that moisture.

With practise, you can become very proficient at reading these profiles ‘as you go’. Without moisture profiles the meter is not much more than a gimmick. This is why specialists like me have had to sit and squirm, whilst evangelistic ‘celebrity surveyors’ have stuck meter probes in their heads and gleefully said (to camera), “it’s beeping away – does that mean my head has rising damp”? No, it means you are an idiot.

So, how do you obtain a profile? Let’s say we are checking the internal plaster on a ground floor wall. We have obtained a high reading, just above skirting board level. All a profile involves is taking progressive readings at set vertical spacing up from that point. Let’s say that we take 12 readings about 100mm apart vertically, starting just above the skirting.

So if the first 5 or six readings were all in the ‘high’ range and the next two were in the ‘very high’ range, with those after reducing very quickly to low. What could that imply?

Well, it could imply that the base of the wall plaster is quite damp, with a slightly damper zone just above that and no damp thereafter. Extend that profile either side and you may find that in effect, you’ve found a tide mark using the meter. A tide mark which you could not otherwise see.

One common reason for this profile is Rising Damp. Rising damp will usually deposit mineral salts from the ground, into the wall it has risen through. The passage of water, up and down stops these salts from becoming too concentrated in the rising damp zone. However, the upper zone, will not be washed in this way and, as salts are deposited at the point of evaporation, they will concentrate here.

Thus, a meter will react to the capillary moisture at the lower level and then will read higher at the upper zone, due to the conductivity of the metallic salts in the plaster here. In humid conditions, the wall at the upper zone may actually be wetter, as water vapour is absorbed by the salts. So does our ‘Rising damp profile’ confirm that there is rising damp? The answer is no, however it does give us a strong indication that rising damp is present. It is up to a surveyor to add this profile to the other evidence, in order to make a diagnosis. Sometimes this can be confidently done, on other occasions, some further work may be necessary, such at gravimetric testing and salt analysis.

There are lots of ‘standard’ profiles, but really, practice is needed because they are not always as clearly defined on site, as they are in a BRE publication.

Some ‘celebrity surveyors’ make much of the effect of aluminium foil behind wall paper; upsetting the readings and such. In practice there’s no real prospect of this cause being mistaken for a real damp problem. If you use a meter more than infrequently, you soon become attuned to natural variations in your readings; the ‘false’ readings from such things as foil are pretty obvious when you come across them.

Keep the batteries fresh and your pins sharp and conductivity meters are an invaluable tool for detecting wet rot, dry rot, rising damp, penetrating damp and condensation.

There are other electronic meters too. Capacitance meters are a minority choice for some. Personally, I don’t find them reassuring in use. They tend to throw up too many false positives for me and cannot be relied on to obtain useful profiles.

If you really want to know the true moisture content of a plaster or masonry sample, that’s easy. Just use a chemical moisture meter or take samples for gravimetric testing. I’ll blog on these later.

Dry Rot.

Excellent, informative article you have written here. It is of great debate the quality of moisture meters on any other materials rather than wood. Both debate parties have both good and bad points. But generally any moisture meter should only be used as a “guide and indication” of moisture content levels rather than a “confirmative measure of content amounts”.

Paul

Hi Paul,

Thanks for looking in. I agree that there has been debate about these meters. However, it is not really a debate in my view… more a sales opportunity for some who would see your meters blamed for every bad damp course sale ever made.

I have posted a new article on the site on this for you…

http://www.preservationexpert.co.uk/damp-specialist-or-anti-damp-specialist-damp-specialist

Good luck with your site by the way – a great resource.

Bryan.

If there is no indication of damp inside the house, how can you be assured that dormers are not leaking into their wooden supports

Hi Vivienne,

Well, that is a hard one to answer. I’d need to survey the house. Remember that a moisture meter is just a tool and is next to useless if used by anyone other than an experienced surveyor. Good visual observations are needed before the meter is even deployed.

Thanks for getting in touch.

Dry Rot.

I asked a question on Sunday 24/04/2016 . It has been removed ! Is this because you do not have the answer?

you could at leased replied to the email that i bothered to type! I certainly won’t bother this site again

Sorry Keith I must have missed it. What was it again?

An interesting and informative article but as someone who has no technical knowledge whatever and just looking for a reason why my little ‘sound only’ meter is making a noise when held on the plaster but not on the skirting board below, I found that some of the information was over my head.

However, could I suggest, purely out of pedantic reasons, if the heading in the fourth section should not refer to roles rather than rolls.

Hi Eva,

Thank you for editing my post! This is quite an old post but is still valid, though I haven’t read it in ages. ROLLS! lol.

It is tricky when I write because my audience ranges very widely, from laypersons to surveyors and other built environment professionals. Sorry if I made this one a bit techy…

I appreciate feedback and I’am grateful you took the time to point out the error 🙂

Take care.

Bryan.

Hi,

I’m new to the industry & studying for my BDMA exam. And perhaps the senior exam within 24 months.

I was looking for the answer to a question.

‘According to PAS64:2013 the acceptable moisture content measured in WME for brick is?’

Your article has helped me understand about density & resistance.

Great information & very easily readable. Thank you.