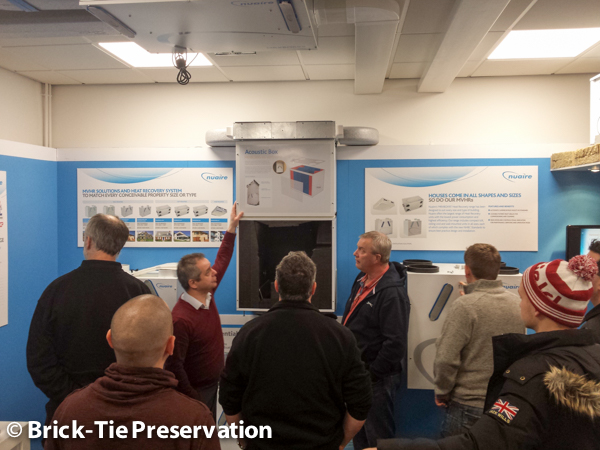

The Bpec class of January 2015 in Nuaire’s impressive exhibition room – Surveyor Paul Glover (center) and David Burton (far right)

The reason behind the course – it’s not just about mould and condensation.

Mould and condensation go hand in hand. As an experienced damp surveyor many of the calls I receive are about mould.

Its smelly, spoils decorations and can aggravate poor health conditions. Of course, as I’ve written before, much of this is due to the changes we’ve all made in the way we live; the way we have modified old housing; as well as the way we build new dwellings. These days’ houses are sealed up airtight and unlike the old days – every night is bath or shower night. In winter especially, windows stream and often, unsightly mould and condensation prosper.

Thanks to the Property Care Association, training in damp diagnosis is now better than ever, but thus far, the training of damp surveyors in the best practical ways of specifying and commissioning ventilation and heat exchange systems has been sparse.

Mould and condensation will not usually happen in a well heated, well ventilated and properly insulated house. When it does, if these things look fine, where do clients and professionals turn next? What can be done and how can it be done well?

Following a glowing recommendation from my good friend and professional colleague David Cook, of Cook group in Hull, I called Nuaire for help and advice.

Nuaire are the UK’s number 1 commercial manufacturer of ventilation and heat exchange systems, with sales of over £50m across the globe. A real Welsh success story, they employ over 400 people on their site in Caerphilly, with many more outside ‘on the road’.

Together with the other main manufacturers of these systems, they worked with and supported bpec to produce the two day course; and test assessment for engineers and others, who might inspect, commission or repair ventilation equipment – this means everything from extractor fans to more complex centralised mechanical extract systems and mechanical extract with heat exchange products.

So I found myself with my damp and timber surveyor Paul Glover, in Nuaire’s HQ with a few others, to spend two days being schooled on the issues surrounding ventilation equipment and inspection.

Noise is a source of pollution and nuisance – not with Nuaire’s acoustic box though… David Burton strips one down for the bpec class

Nuaire’s Residential Service manager David Burton was our tutor and guide.

The course was divided into four modules:

- Domestic Ventilation in context

- Airflow requirements and calculations

- Specific ventilation health and safety requirements and,

- Installation, inspection, testing, commissioning and provision of information.

The context of ventilation should have been a simple revision for me; however, I found that I lacked sufficient knowledge of the legal framework surrounding ventilation. I now know the importance of the Building Regulations approved documents Part F (means of ventilation), and how other parts of the Building reg’s, like P electrical; J Combustion appliances, L Conservation of fuel and power in new buildings and M Access to and use of buildings apply.

There are four main systems described in part F of the reg’s and these were explored:

- Intermittent extract fans and background ventilators; System 1

- Passive Stack Ventilation; System 2

- Continuous mechanical extract ventilation; System 3 and

- Continuous mechanical balanced ventilation with heat Recovery; System 4

Alternative types, which don’t fit the above, were covered too, including Positive input ventilation and single room heat recovery ventilators.

Maths isn’t my strong point but thankfully the airflow requirements and calculations sections were straightforward and well tutored by David Burton. These are crucial in deciding on the right ventilation equipment, size of ducts, background ventilators – even gaps under doors and the number of bends allowed in ducting – all great stuff to know.

Health and safety is my bag so I enjoyed this bit even if some of my classmates were a tad bored by it. It was all essential stuff and David’s tale of a chap who died sitting by his fire, because that day he’d had an extractor fan fitted which was too powerful and drew in the fire’s toxic fumes, was an eye opener.

Module four was fascinating. I’m sorry, but before this course I confused installation with commissioning. I see installed extractor fans and PIV units almost daily, in my surveying work. Now I’ve done my bpec, I know that I rarely see ‘commissioned’ ventilation systems.

The calculations and where they come in when commissioning ventilation systems, to control mould and condensation.

Commissioning is about much more than just forming a hole in a wall or ceiling and wiring up a fan. Commissioning is at the heart of good practice and is the essential component of achieving a dwelling which is free of mould and condensation.

This involves checking the equipment is the right thing for the house – it’s size, and occupancy levels. Defining the flow rates which are needed and ensuring that the installation does not compromise the designer’s intentions. It’s no good fitting a well designed and manufactured MEV and then choking the life out of it, with lots of flexible ducting, kinks and excessive bends or restrictive extract terminals.

Even when the installation is all well and correct, commissioning involves on-site testing to ensure that the completed unit is performing as intended.

Flow rates at each terminal;

Background Ventilators and intermittent extracts (via part F system 3 table A)

Kitchen minimum 30l/s (near hob)

60l/s elsewhere in the kitchen

Utility 30l/s

Bathroom 15l/s

Sanitary accommodation

(cloaks and such) 6l/s

For continuous ventilation it gets a bit more complex:

There is a ‘whole dwelling ventilation rate’ based on the number of bedrooms. However this is then checked against the total area of the dwelling (in case the proportional area of other habitable rooms is high), and the occupancy level.

This is then balanced against the individual room rates in table b.

Kitchen 13l/s

Utility 8l/s

Bathroom 8l/s

Sanitary accommodation 6l/s

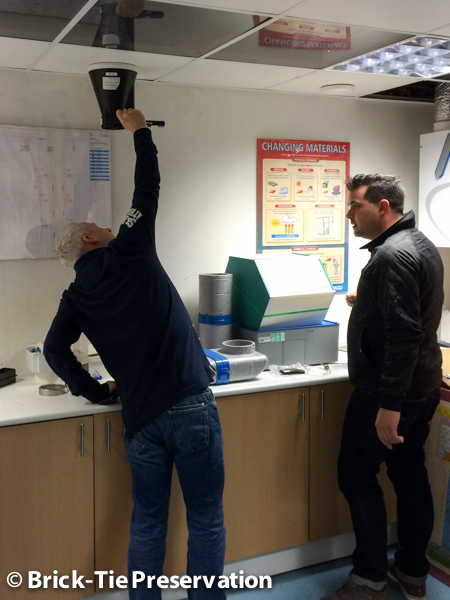

The author measuring the flow rate of an extract terminal as part of the balancing of a branched ducting system

Whilst these rates are lower than for intermittent, it should be remembered that these are ‘continuous rates’. A further ‘boost’ rate will be much higher, for use in the kitchen or bathroom, to purge the smell of burnt toast or other less pleasant things and of course get that extra water vapour out, when cooking or washing is in progress.

Further tweaks are needed when dealing with continuous balanced ventilation with heat recovery. These systems work best in airtight houses (<5m3/(h.M2) at 50Pa. There’s little point trying to run these in a very leaky house. This makes them inefficient. If despite this, a client wants one – then the calculated whole dwelling ventilation rate can be reduced by 0.04l/s, to take account of the fact that there’s more than enough fresh air getting in anyway; to make more holes would be unreasonably wasteful of the heat the client wishes to recover.

No ventilation fitter or inspector should be without a UKAS calibrated anemometer, with the essential correction factors to take account of the hood characteristics

A few golden rules from the Bpec course:

- Extract only from wet rooms. If this seems obvious I visited a house in Leeds only the other week, which had constant running extract fans in two of the bedrooms (doh)

- All ducting, which passes through a loft/unheated area, must be insulated – must

- The maximum length of flexible duct on an axial fan (propeller type blades) is 1.5M and it must be stretched to 90% taut. For a centrifugal fan the maximum is higher but is subject to restrictions depending on the extract rate and the number of bends.

- Vertical ducting requires a condensation trap – always

- All ducting should be adequately supported along its length

- You can’t use ‘duct tape’ on ducting (it dries out and peels off).

- Where possible use rigid duct – it offers less resistance and is more robust

Background ventilation is essential, though as mentioned above, must be reduced slightly,if the system needs an airtight house and supplies it’s own air (MVHR).

However, the images below are becoming increasingly frequent as I survey around Yorkshire – good education and information for tenants, owners or those managing buildings is crucial. It is also part of the commissioning process, which is defined within the bpec course and meets the requirements of Part F of the building regulations (means of Ventilation).

This switch is for the electrician and should be in the on position – often switched off to save money or silence a noisy fan

Conclusions.

If an old hand like me can come away from a course with a smile, knowing that I’ve made mistakes and can now avoid them – well that is a very good thing.

I now know that very many of the ventilation systems I’ve seen are not working because ‘they were never commissioned’. Furthermore, I can test and then commission them for my clients.

I’ve managed up to now because in the past, mould and condensation was nowhere near as endemic as it now is. The UK’s housing stock is evolving to fit new lifestyles and energy saving compliance. If ill health and miserable living conditions are to be avoided we must all know this stuff.

My thanks go to Nuaire and bpec for providing such a well-balanced and comprehensive course. I am also very grateful to David Burton, who was patient, enthusiastic and supportive (a good laugh too).

I was already a Nuaire fan (excuse the pun), having specified very many Cyfan’s, Drymaster and Flatmaster units.

Part F of the building regulations demands that all ventilation systems must be commissioned. This applies to new build and retro-fit. Now I know much more about ventilation I can specify with greater confidence, knowing that my recommendations are legal, proportionate and effective. I’ve ordered a new Testo Anemometer and hood set from BSRIA and can’t wait to get started!

Dry Rot.

Hi Bryan,

Excellent as always, I really enjoyed my time with Nuaire doing my BPEC.

The BPEC is a must, which has given me a greater understanding of building ventilation.

Keep up the posts 🙂

Thanks Ross,

Yes, it was good mate. It’s great that so many PCA members are on these now, apart from the usual electricians and ventilation engineers.

best wishes

Dry Rot

Another great article Brian, very informative. Do nuaire run courses for everyone or just for the damp yoda’s like yourself?

Hi John,

Thanks for looking in. You need to apply and of course they are keen to train people who may install or recommend installation. Apart from that, it’s all good. Give them a call mate, you’ll enjoy it.

Bryan

Very nice and very accurate write up Bryan, well done! :o)

Thanks Bryan good write-up, very interesting. You can almost always guarantee that extractors are turned off at the isolator as pictured!

Regards,

James

Hello Bryan,

A very interesting and enlightening write-up, it has encouraged me to undertake the same course if they’ll have me, I have seen so many ventilation installations where they are ineffective, but if I had the knowledge to fully test the installation, I feel it would be so much more use to my clients.

Here’s hoping I can get myself and colleague booked in!

Dave Taylor

Hi David,

I’m glad you are inspired to learn more – me too, I never stop learning.

bryan

Hi Michael, I recommend you download ‘The domestic ventilation compliance guide’. It is written in plain English and sets out how ducting should be done.

Good luck with it.

Dryrot